The ideal running clearance is 0.0025".

The ideal running clearance is calculated at 0.0025”. When honing to achieve your final bore size. It is recommended that at least 0.002 to 0.003” is removed in the honing process using M3F finishing stones.

These pistons have been picked to be within 2 grams of balance but can be balanced to tighter tolerances if required.olérances si nécessaire.

Make sure they are thoroughly washed. A final wash should be with the pins installed into the pistons. This will enable the pins to be free moving before press fitting onto con rods.

Pistons will need to be interference/press fitted by a professional.

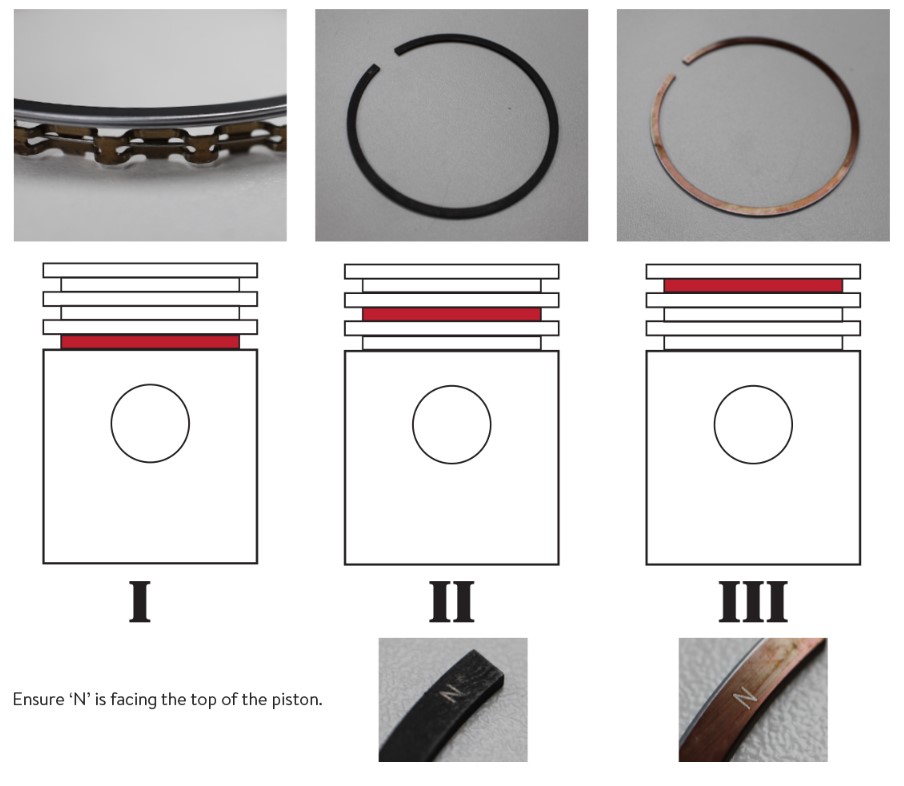

Piston rings need to be carefully washed and then assembled onto the pistons. See piston ring fitting guide for which groove each ring should be installed.

Make sure the piston ring gaps are equidistant apart.

This piston set can be used with both floating and press fit type applications/con rods. The only difference is that when used with the press fit con rod type, the circlips are not used. The press fit con rod uses the same diameter wrist pin as that of the floating pin type. Note that small-bore pistons are orientated, denoted by either an arrow or dimple in the piston crown. The marks need to face towards the coolant pump end of the block.

These pistons are manufactured from a far superior aluminium than most high performance pistons. They contain a much higher silicone content and advance heat treatments which creates a more stable piston. This dramatically reduces expansion under combustion/running conditions. Consequently lower piston to bore clearances are required. They are manufactured for race use so will give correct piston to bore clearance on the relevant bore size. Suggested finished honed bore to piston clearances are as follows :

Road/fast road : 0.0015” to 0.0017” (0.0381mm to 0.0432mm)

Sports/super sports : 0.0018” to 0 0.002” (0.0457mm to 0.0508mm)

Race 0.0022” to 0.0025” (0.0559mm to 0.0635mm)

IMPORTANT - Because the standard available gaskets over-hang the bore on the +0.080” and and +0.100” bore sizes, make sure the piston crowns are at least 0.010” below the block face when at top dead centre. For blocks that have already been re-faced sufficiently so it is either already flush with the piston crowns at top dead centre or the pistons actually protrude from the bore – either machine the piston crowns to give the desired crown to block face clearance, or machine a chamfer on to the top edge of the piston crown.